We are celebrating five years [in] Session, however, our design story began years before our launch. From an idea in our brains to something you can touch.

Scroll with us through the process of designing the award-winning Session Bong.

A note from Esther,

Inspiration for the Bong

October - three years before our launch

We found ourselves in Heath Ceramics on an inspiration trip.

Perched on a shelf was a series of glass decanters, we particularly were draw to the Swedish-designed Rainman Decanter. The piece is simple with the pour spout being the main design detail. It embodies the understated elegance inherit in Nordic design.

We were attracted to the shape, the minimalist details, and how the design celebrated the glass as an element. We began looking deeper into barware vessels and decanters for inspiration because these items have a history of being displayed in living rooms.

Project Scope

January - two years and ten months before launch.

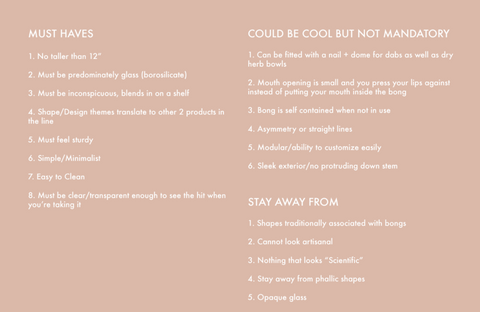

After three months of inspiration finding, we meet to align on the scope of the project. For any Session product we start with a slide that defines: must have's, could be cool's, and boundaries.

For the Bong we aligned on the following:

Sketch-Storm

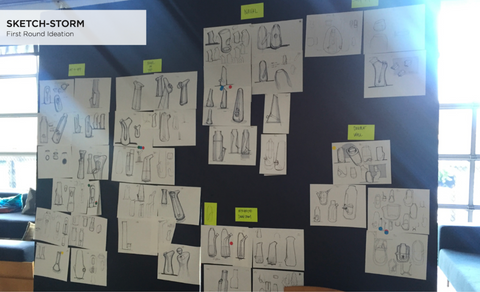

January - February - two years and eight months before launch.

Like the name implies, we brainstorm and sketch. These meeting are fast paced, and collaborative. An idea from one person is built upon by another and no idea is judged.

As we sketch, some concepts will begin to feel more exciting than others and common themes emerge like cut outs, or fluted details. We organize the themes into concept groups and share the ideas with friends in a focus group for feedback.

First Focus Group

March - 2 years and seven months until launch.

Every product we produce has been shown to focus groups multiple times throughout its design journey. We find these feedback sessions invaluable when it comes to creating simplified designs without sacrificing function.

For the Bong, we spoke to two focus groups: people who frequently use bongs and people who are new to Cannabis.

Concept Selections

April - 2 years and six months until launch.

The focus groups help whittle down the concepts, some are immediate "No"s to the group and others are cut after a few rounds of interviews. In the case of the Bong, we have a clear winner in the concept we've dubbed the Navel.

The design features a simple glass body with a belly button dimple that houses the bowl.

CAD Rendering & 3D Printing

May - two years and six months before launch.

The Navel has been approved as a concept so the time has come to translate the design into 3D file format and begin prototyping with 3D prints. At this stage we are trying to determine subtle details like the bowl design and overall proportions.

We've finalized the ideal design though the 3D prints. We update the technical spec sheets and send the 3D files to our factory to begin the first glass prototype.

Glass Prototyping

August - two years and two months before launch.

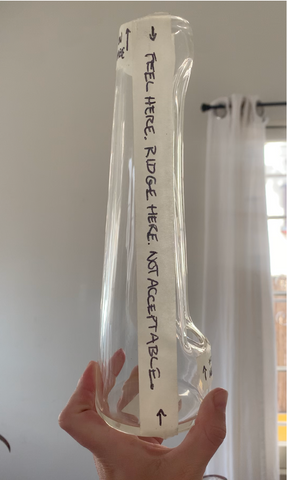

Despite the simplicity of the initial design, translating it into glass was not simple.

Most borosilicate glass bongs are made by joining tubes of glass together with all sides symmetrically rounded. The indent proved so difficult to make our American glass factory told us it was impossible.

It took three factories before we found a facility that could make the indent. The Bong requires multiple molds and precision timing to execute without the glass walls collapsing.

Once the indent was possible edits to the bowl and downstem design had to be made. Originally we wanted a larger jointed bowl, but making a hole that would accommodate a 14mm bowl caused the indent to collapse.

Unapproved bowl iteration

Two months of problem solving and video calls with our factory in China, our first prototype arrived and it was still a mess.

In total it took eight prototypes and 18 months for the design to be approved for production. Over the duration of these samples we refined the precision of the pieces and tested applications of silicone.

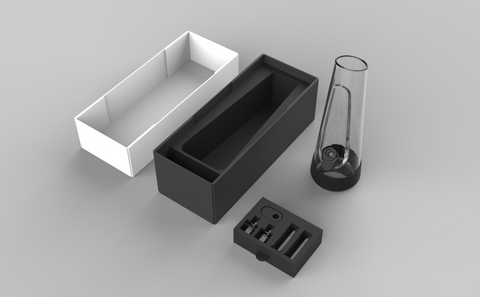

Packaging Concept

May - five months before launch

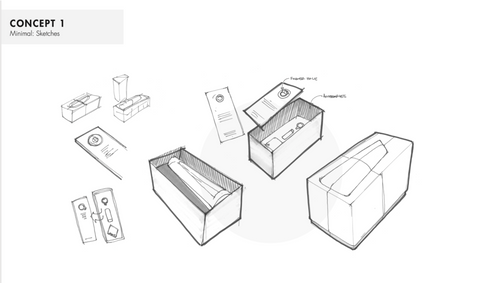

Most bongs come wrapped in bubble wrap. Another signal that these items are often overlooked or after thoughts. As stoners, we wanted people to feel their cannabis use is not only valid, that it should be celebrated.

Our goal when designing a box for the Bong was to protect the glass, while also making the first experience with our brand feel special.

The packaging design came together significantly faster than the Bong because we were able to produce prototypes in-house. Once we had finalized the style of the box and the unboxing experience, our sample was sent to the factory for production.

Final Focus Group

June - four months until launch

We have a sample of the Bong that looks almost perfect and the packaging finalized.

At this stage we invite our focus groups back for a review. Instead of looking at individual design elements, the goal of the final focus group is to watch people interact with pieces and to understand what information or instructions we need to provide to our customers.

One example is the lighter pass in the indent. This was not designed as a feature but was observed when we watched people in the focus groups using the Bong.

Production begins

July - 3 months before launch.

We place our order for the first 200 units. It's taken almost three years to take a concept from idea to physical product. We spent the rest of the summer building our website, and organizing photoshoots.

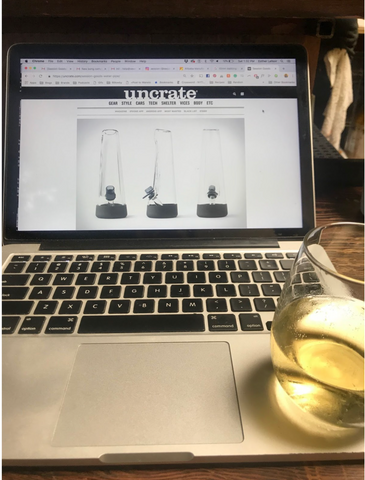

Launch & Reception

We sell our first Bong on October 20th, 2018, within 3 weeks the first run of 200 Bongs has sold out.

In 2019 we win three design awards two from Core 77 and a packaging award from The Dieline.

The Bong is patented for Design & Utility in United States, Canada and the EU.

![[in] session blog — Inspiring interviews, articles about cannabis & design](http://sessiongoods.com/cdn/shop/files/session-goods-homepage-insession-blog-mobile_63644ba1-0223-434b-b77e-5f4a30d7375f.webp?v=1692127377&width=600)